Build Quality

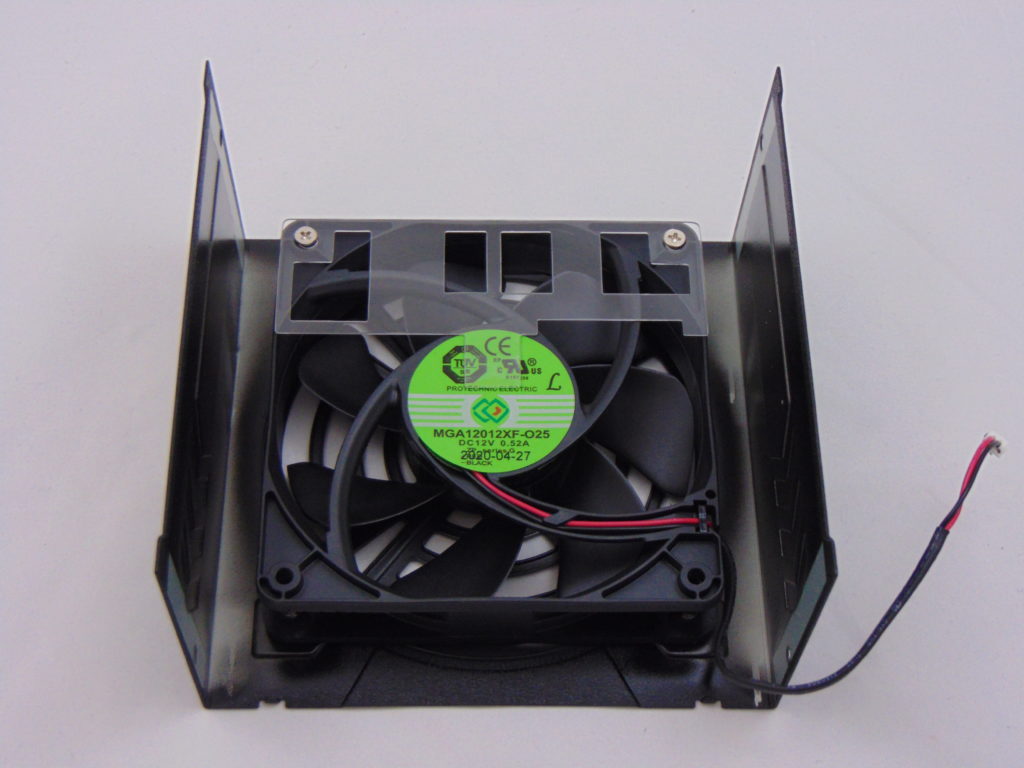

As we already know the FSP Hydro G PRO 1000W features a single 120mm fan design like many other offerings on the market that has come to be the preferred standard for quiet cooling environments due to the ability to move a larger volume of air at slower speeds than a smaller diameter fan. While great for quiet computing environments the key criteria in our evaluation is whether or not the cooling solution is sufficient, not necessarily it’s sound level or form factor.

External Build Quality

The external build of the FSP Hydro G PRO 1000W follows in form that of many other ATX12v/EPS power supplies (including FSP’s own, earlier, Hydro series units). The finish we see today is a highly textured black, that should be durable, and the unit carries the FSP Hydro G PRO branding. The branding is, however, applied via stickers. The modular interface is labeled well but it is, again, done so with a sticker. Other than that, the rear of the unit features a switch labeled “ECO” (which changes the fan controller behavior), and there is a printed slogan on of “Power Never Ends” (the Roman Empire would like to have a word with FSP). Lastly, the fan guard is probably, simultaneously, the most interesting and also the most indecipherable part of the external build quality.

The FSP Hydro G PRO 1000W comes in at a total length of ~5 7/8 inches while the cables come in at a length of ~21″ to 29″ to the first or only connector. Additionally, the cables are all the FlexForce style cables.

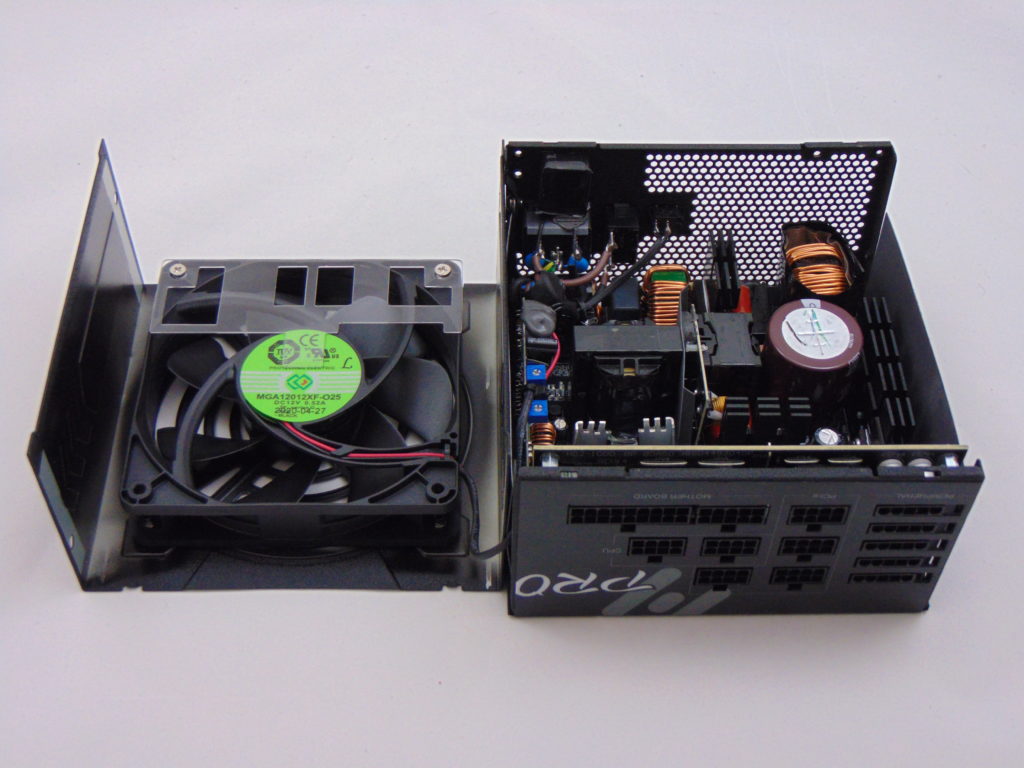

Internal Build Quality

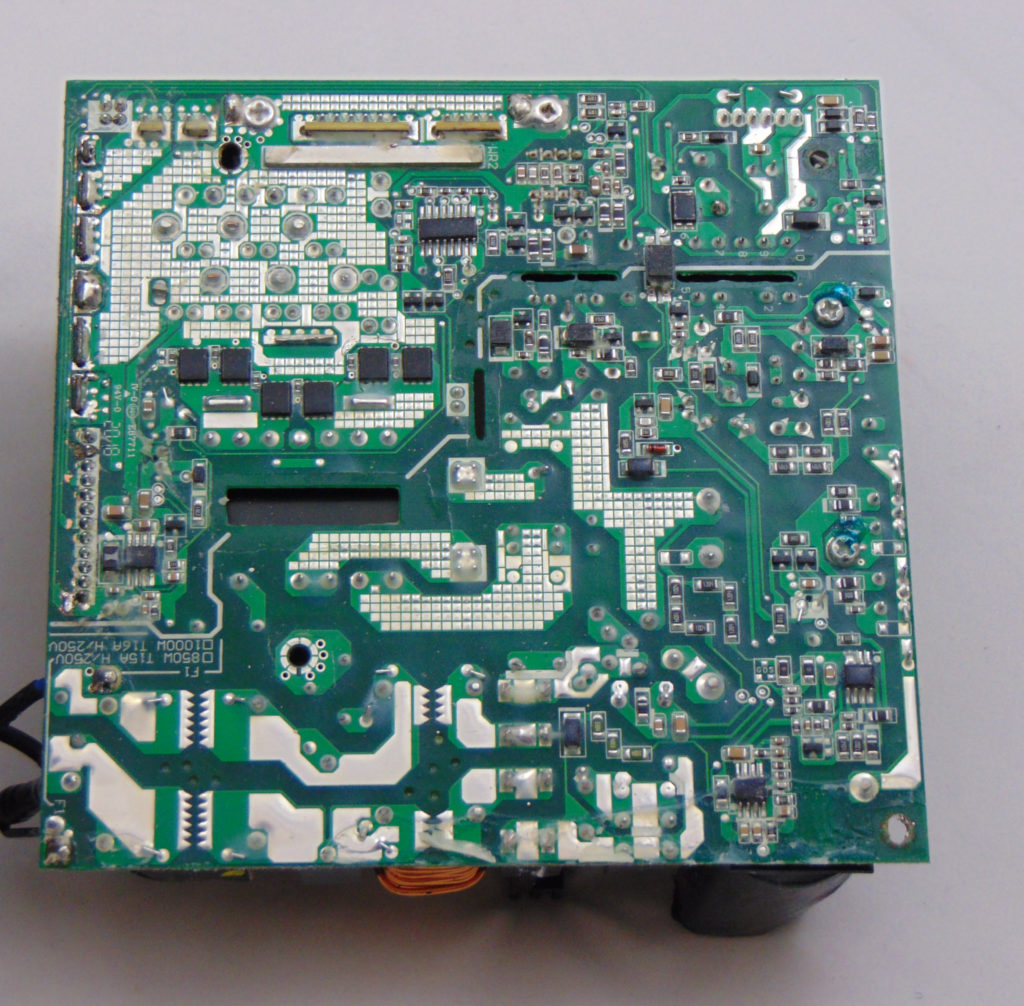

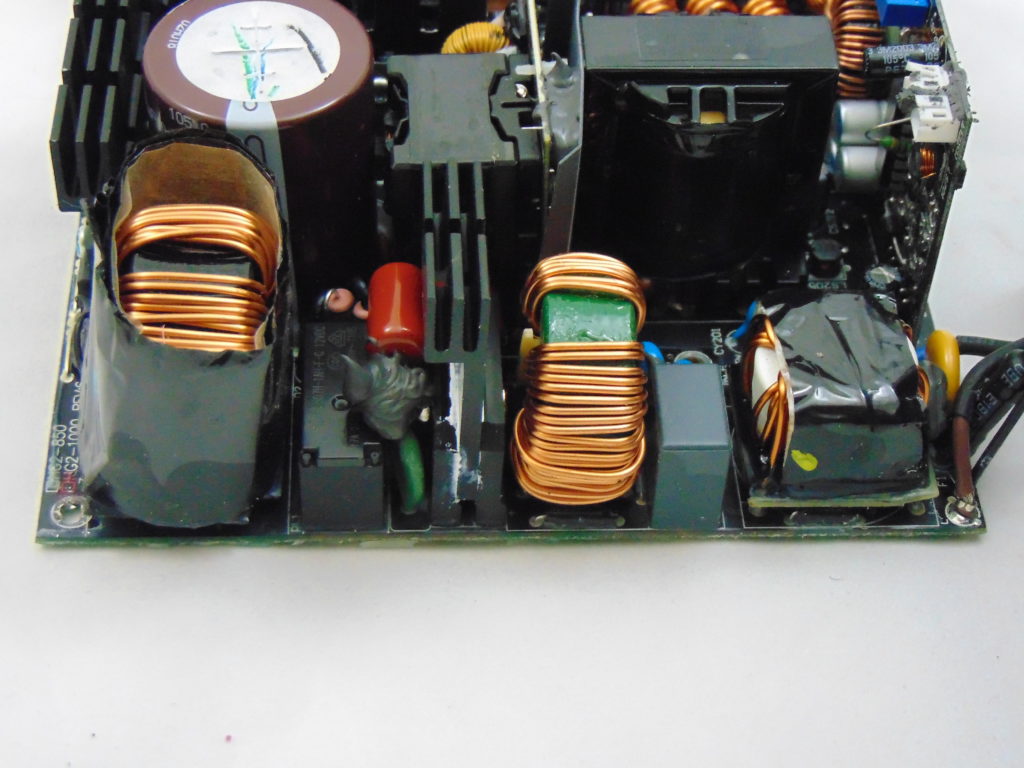

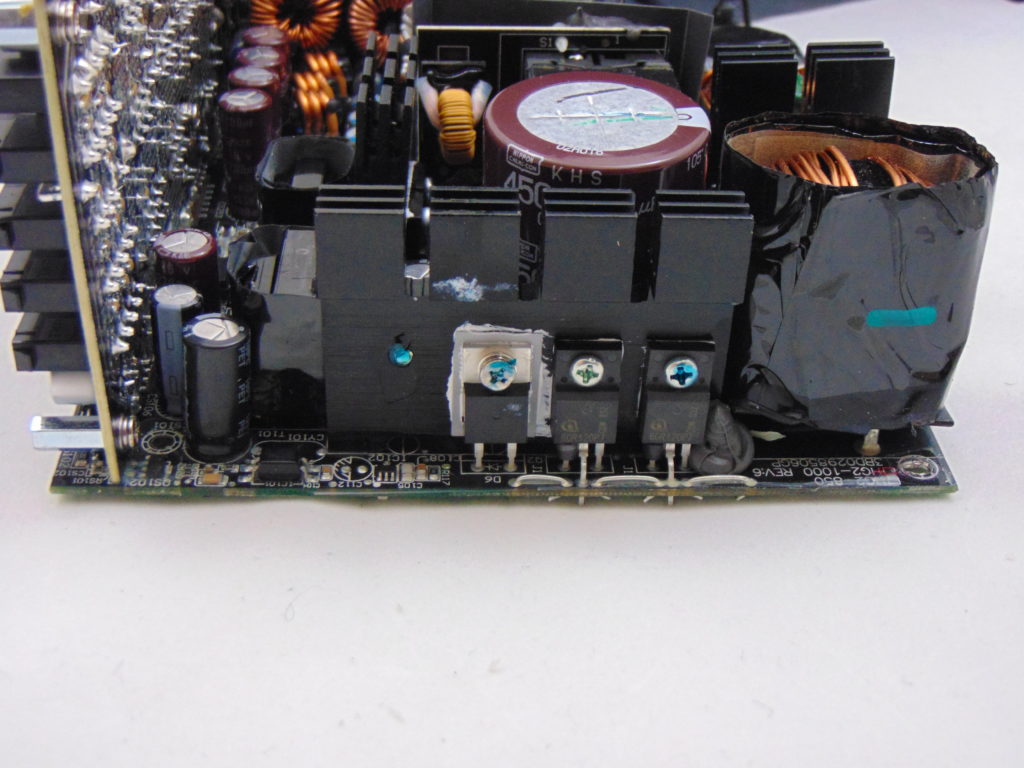

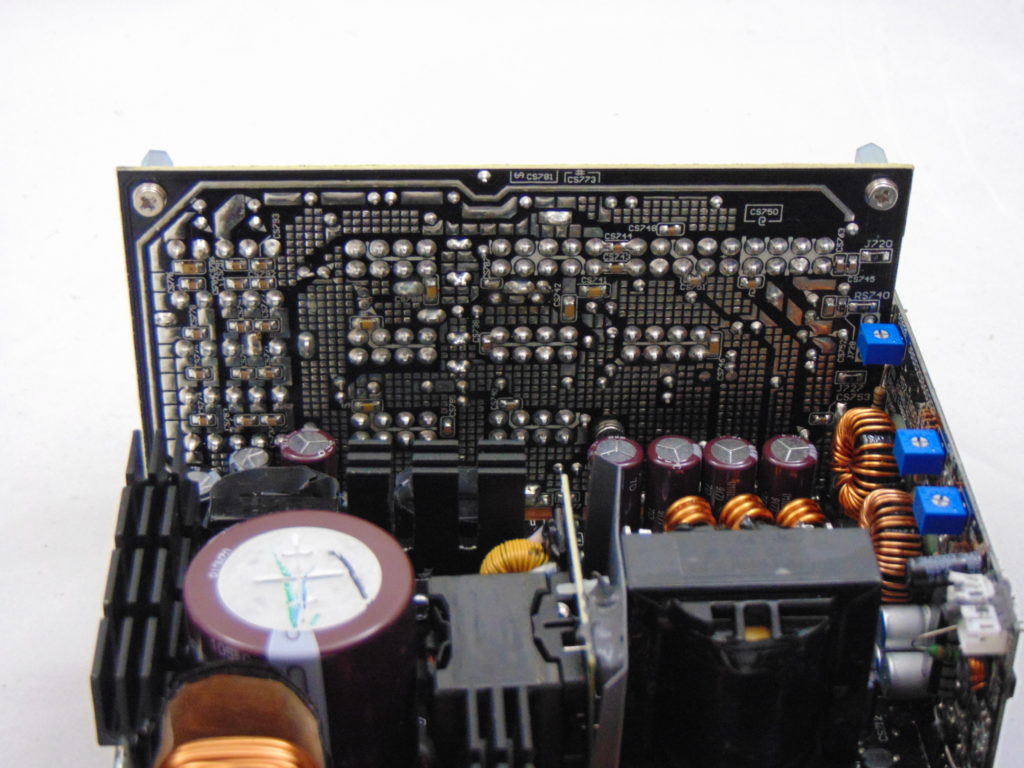

Once we open the top of the Hydro G PRO 1000W, we see a very open design that is unique to the models we have seen. The topology is a half-bridge resonant LLC primary and a secondary where we have synchronous rectification with DC-DC VRMs for the minor rails. The heatsink layout is very sparse with what appears to be just five small heatsinks installed today. The fan paired with these heatsinks is a 120mm FDB fan provided by Protechnic and rated at 0.52A at 12v. When we look at the back of the PCB, we see the 12v MOSFETs here using the housing as an additional heatsink. The soldering here is very good.

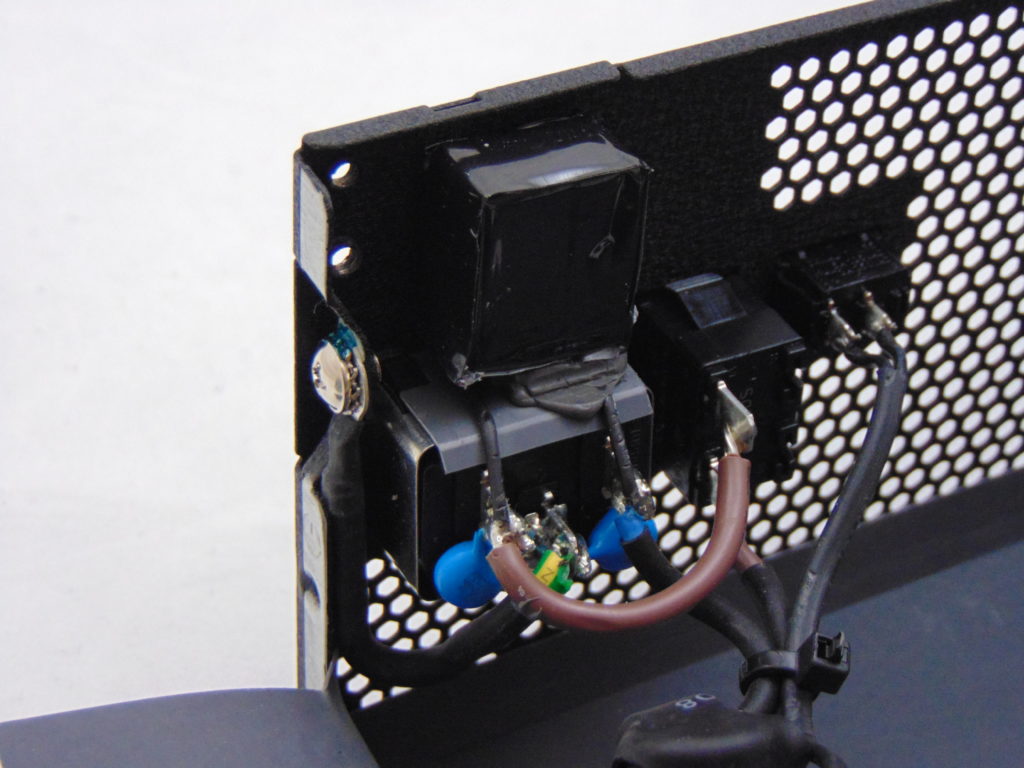

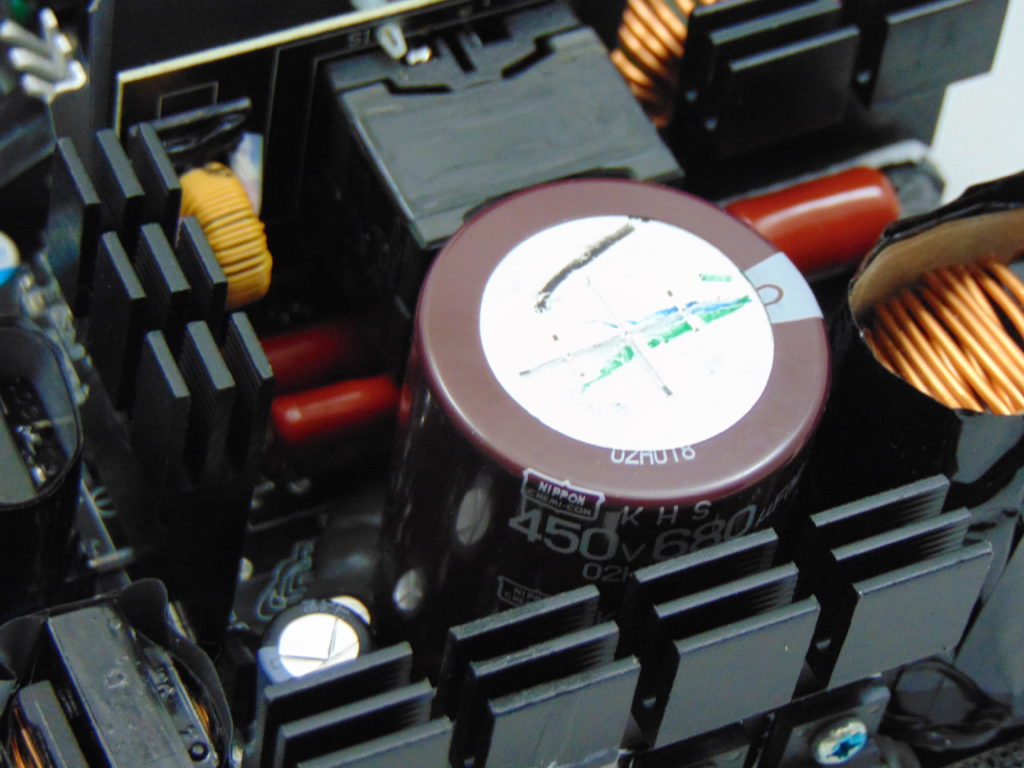

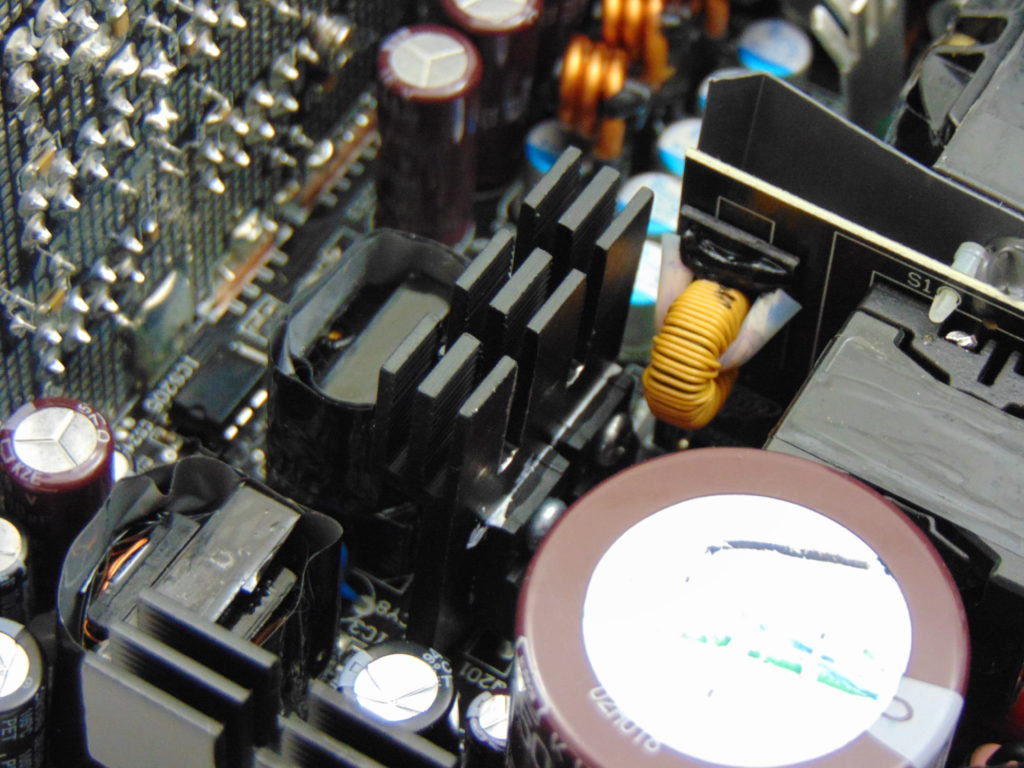

On the primary side, the Hydro G PRO 1000W input filtering begins up on the housing itself with some X capacitors and Y capacitors and then trails onto the main PCB. The bridge rectifiers are next and they are attached to a heatsink making something of a sandwich here. As we move around to the primary side proper, we find a coil followed by the APFC power components on a heatsink. Also located here, we find the main input capacitor which is provided by Nippon Chemi-con. This capacitor is rated at 450v 680uF 105C. There are also a few random Rubycon capacitors in this area. Lastly, the main switchers for the half-bridge LLC primary are attached to the ridged heatsink located towards the middle of the unit.

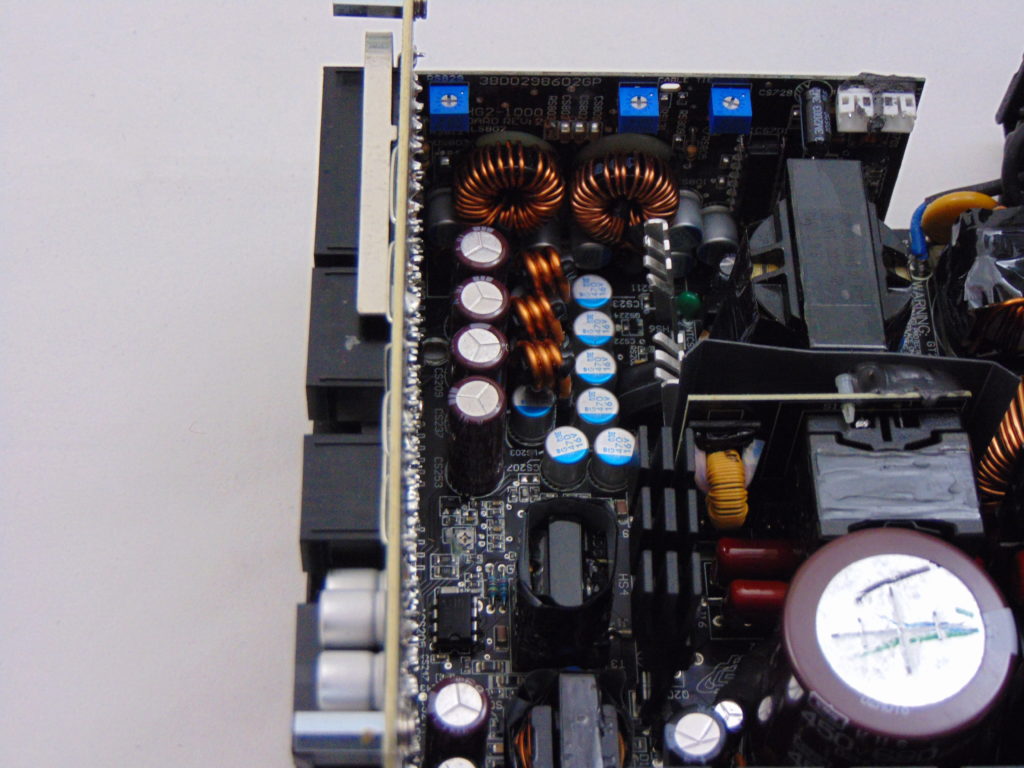

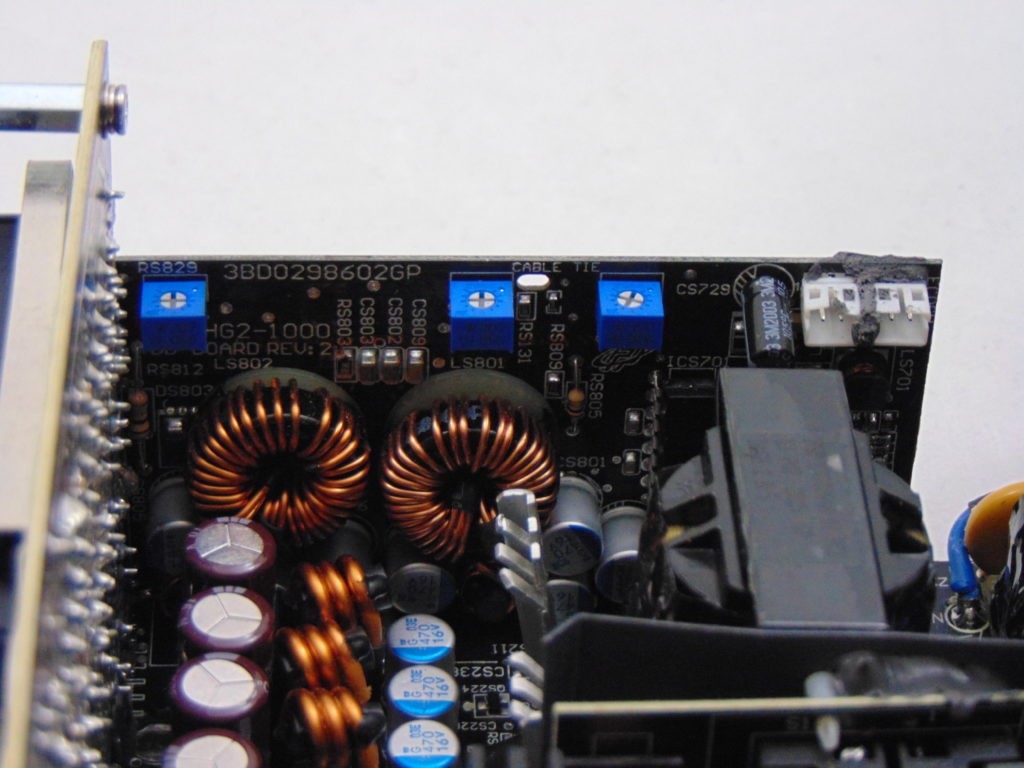

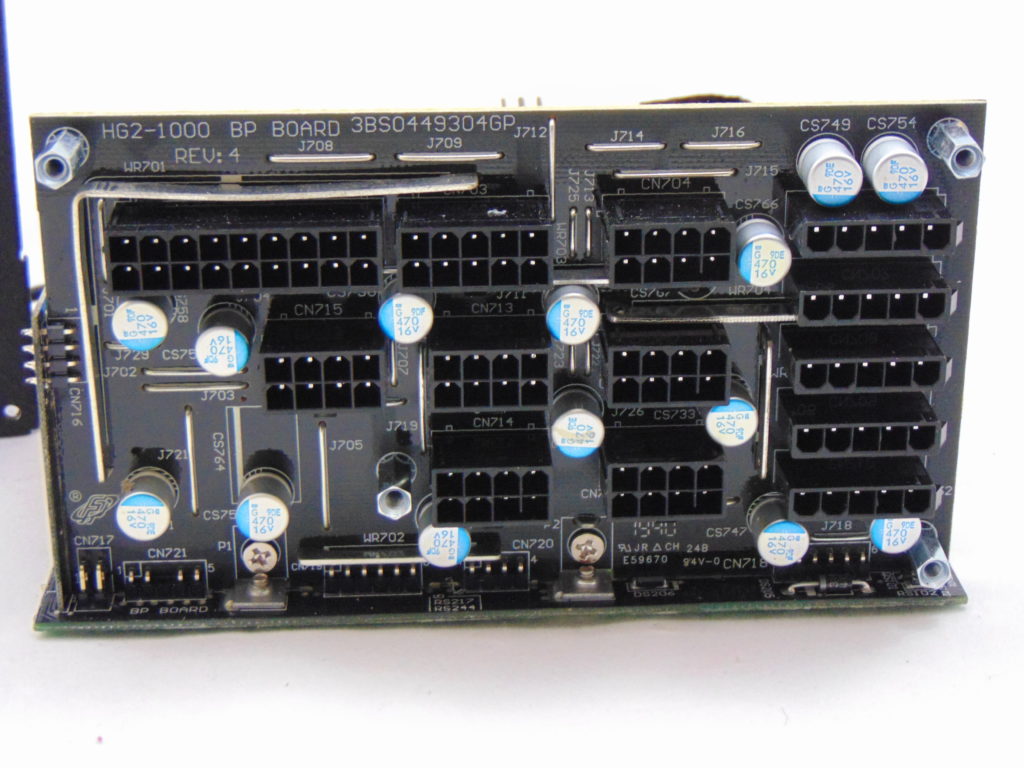

Not exactly part of the secondary, but located nearby, is the +5vsb circuit on its own PCB. The secondary side of this unit is rather open and almost “airy” feeling. In this area, we find the main transformer, a PCB housing the protection IC, and of course the DC-DC VRMs. These VRMs are housed on their own PCBs and we see a few solid Nippon Chemi-con capacitors populating these as well. Additionally, there are a few small Nippon Chemi-con capacitors scattered throughout the secondary in various places and roles in both solid and wet form. We also find small heatsinks that are helping to cool 12v power components in this synchronous rectification design. Moving on to the modular PCB, we see the modular connectors as well as several capacitors provided by Nippon Chemi-con. The PCB construction looks to be excellently executed just like the main PCB.

Build Quality Summary

Today’s FSP Hydro G PRO 1000W is the first ATX12v/EPS power supply we have seen from FSP here at TheFPSReview and it starts off things with a bang (well, hopefully, not literally a bang). The exterior of this unit is well built, and it looks like most modular overhead fan units these days. It does feature a more textured finish than most and an interesting fan guard tp make it stand out just a bit. Some of the actual branding approaches are a bit lower down the quality scale but, ultimately, this does not affect the unit in a major way. Then, just to spice things up again, we see that all of our cabling is the flat FlexForce style cabling. When we move to the interior build quality, we see a modern design that is well executed. The component selection is excellent as we see Nippon Chemi-con and Rubycon standard capacitors as well as Nippon Chemi-con solid capacitors today. This all looks excellent. So, let’s move on now to the load tests and see how this unit does there!