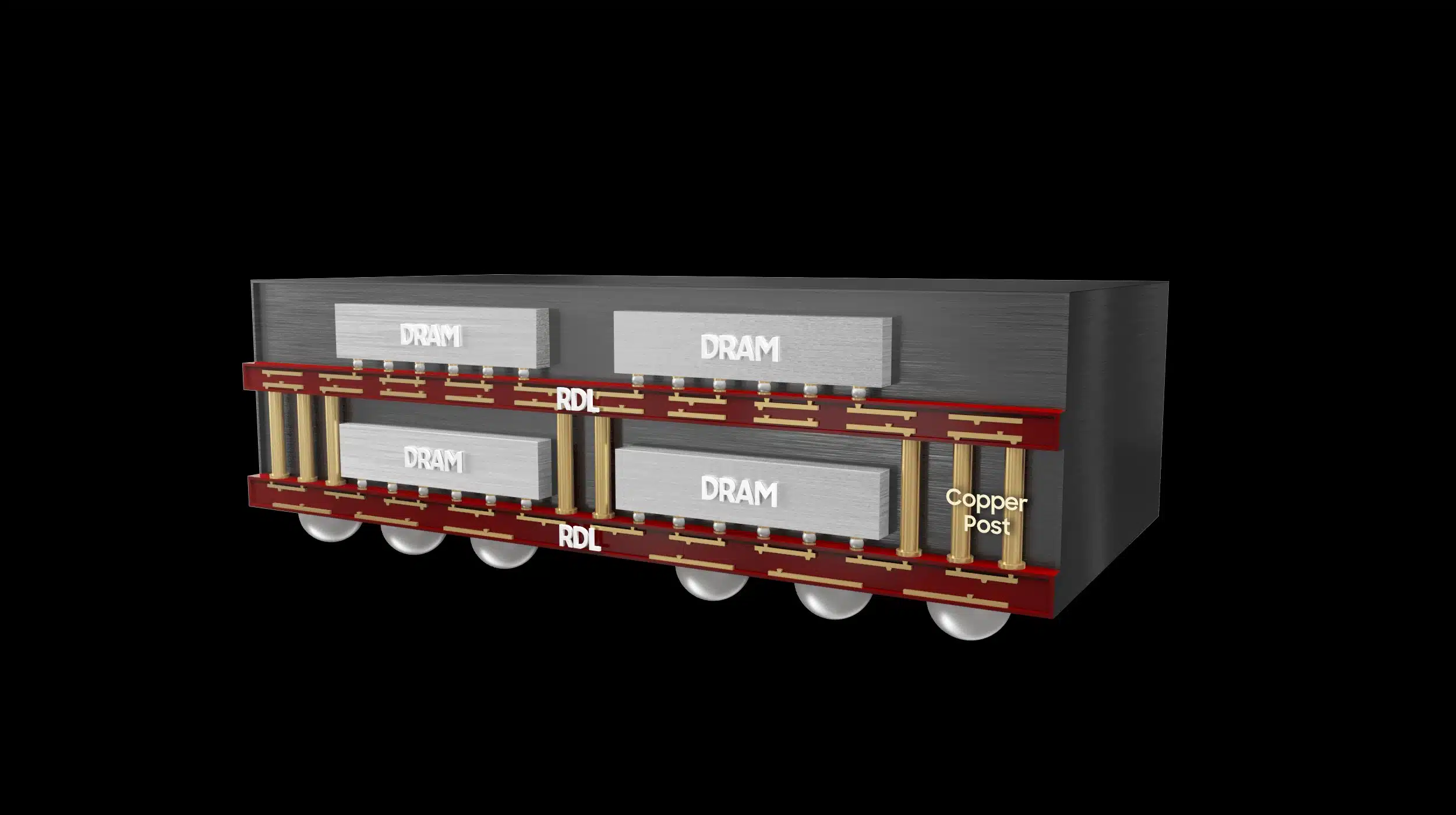

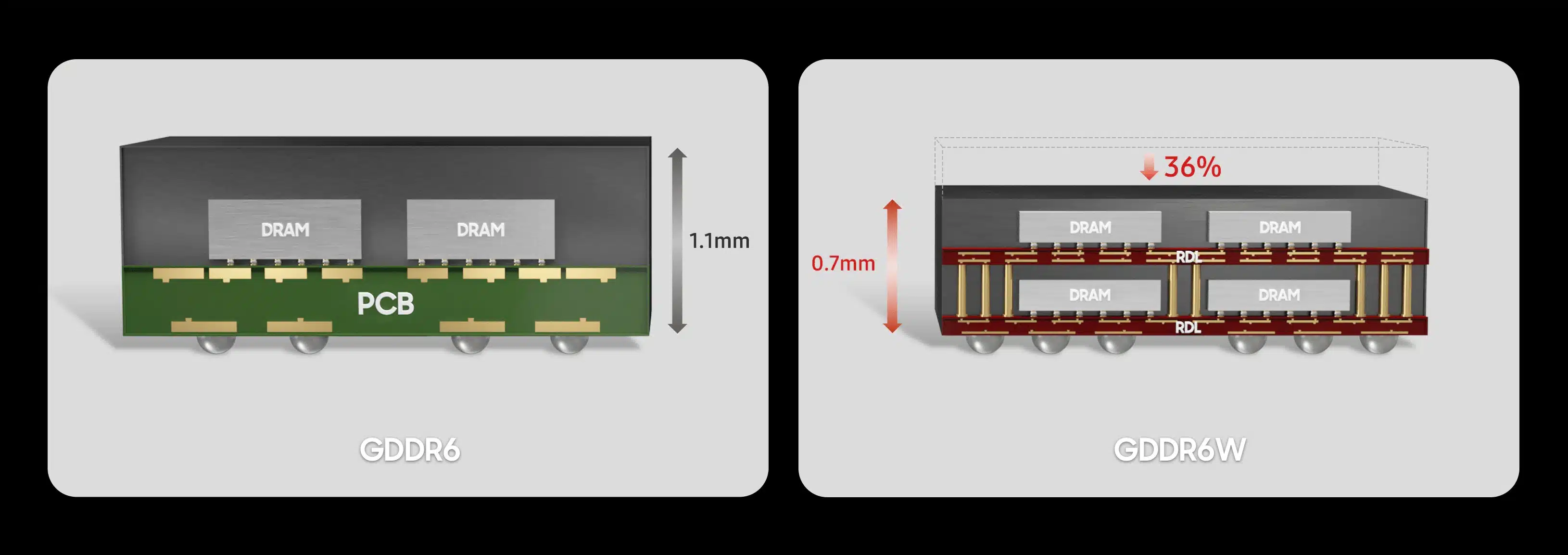

Samsung has announced that it has developed GDDR6W memory with double the bandwidth and capacity of GDDR6. A new package design allows GDDR6W (x64) to surpass GDDR6 (x32) by using Fan-Out Wafer-Level Packaging technology (FOWLP). FOWLP technology, along with a PCB-less architecture, enables twice as much memory while actually reducing the size of the package. The PCB has been replaced by a Re-distribution layer (RDL) that also improves heat dissipation and more efficient wiring patterns. All of this combined has achieved a 36% size reduction over the previous GDDR6 memory.

“By applying an advanced packaging technology to GDDR6, GDDR6W delivers twice the memory capacity and performance of similar-sized packages,” said CheolMin Park, Vice President of New Business Planning, Samsung Electronics Memory Business. “With GDDR6W, we’re able to foster differentiated memory products that can satisfy various customer needs – a major step towards securing our leadership in the market.”

From Samsung GDDR6W Press Release

“Generally, the size of a package increases as more chips are stacked. But there are physical factors that limit the maximum height of a package. What’s more, though stacking chips increases capacity, there is a trade-off in heat dissipation and performance. In order to overcome these trade-offs, we’ve applied our FOWLP technology to GDDR6W. FOWLP technology directly mounts memory die on a silicon wafer, instead of a PCB. In doing so, RDL (Re-distribution layer) technology is applied, enabling much finer wiring patterns. Additionally, as there’s no PCB involved, it reduces the thickness of the package and improves heat dissipation.

The height of the FOWLP-based GDDR6W is 0.7mm – 36% slimmer than the previous package with a height of 1.1mm. And despite the chip being multi-layered, it still offers the same thermal properties and performance as the existing GDDR6. Unlike GDDR6, however, the bandwidth of the FOWLP-based GDDR6W can be doubled thanks to the expanded I/O per single package.

Packaging refers to the process of cutting fabricated wafers into semiconductor shapes or connecting wires. In the industry, this is known as a ‘back-end process.’ While the semiconductor industry has continuously developed towards scaling circuits as much as possible during the front-end process, packaging technology is becoming more and more important as the industry approaches the physical limits of chip sizes limits. That’s why Samsung is using its 3D IC package technology in GDDR6W, creating a single package by stacking a variety of chips in a wafer state. This is one of many innovations planned to make advanced packaging for GDDR6W faster and more efficient.

The newly developed GDDR6W technology can support HBM-level bandwidth at a system level. HBM2E has a system-level bandwidth of 1.6TB/s based on 4K system-level I/O and a 3.2Gpbs transmission rate per pin. GDDR6W, on the other hand, can produce a bandwidth of 1.4TB/s based on 512 system-level I/O and a transmission rate of 22Gpbs per pin. Furthermore, since GDDR6W reduces the number of I/O to about 1/8 compared with using HBM2E, it removes the necessity of using microbumps. That makes it more cost-effective without the need for an interposer layer.

| GDDR6W | HBM2E | |

| The number of System Level I/O | 512 | 4096 |

| Pin Transmission Speed | 22Gbps | 3.2Gpbs |

| System Level Bandwidth | 1.4TB/s | 1.6TB/s |

• System Level: Using graphics cards as an example, setting reference points of 8 package GDDR6W and 4 package HBM.”

Samsung completed JEDEC standardization for GDDR6W in 2Q22 and has announced it will begin its application with small form factor devices first. It will work with its GPU partners to roll out the new memory to notebooks and AI high-performance accelerators, and HPC applications. Samsung also noted in its press release that ray tracing and increased resolutions, such as 4K and 8K, have largely driven the need for faster memory with larger capacities.

“Ray tracing enables the collection of light information to determine the color of each pixel through real-time calculation. This kind of calculation requires the near-simultaneous computation of substantial amounts of data — between 60 to 140 pages worth for one second of an in-game scene. What’s more, display quality is rising fast, with resolutions rapidly transitioning from 4K to 8K standard, while frame buffers1 are increasing to expand two times more than existing ones in response. That’s why high capacity and high bandwidth are essential to meeting the growing memory demand as games continue to develop.“