Intel and its researchers are developing new ways of cooling down next-generation architectures, including power-hungry devices that are capable of drawing up to 2 kilowatts, according to a new article that the chipmaker shared today titled “Intel Dives into the Future of Cooling.” One of the methods that Intel is looking at include 3D vapor chambers, which appears to complement the concept of boiling, while another is using fluid jets, a customizable solution, to route fluid. Critics of Intel say that this is all par for the course for the company, with desktop CPUs like the Core i9-13900K typically appearing pretty high in power consumption rankings.

From an Intel Newsroom post:

Among the solutions they are looking at are 3D vapor chambers (sealed, flat metal pockets filled with fluid) to spread the boiling capacity using minimal space and improved boiling enhancement coatings, which reduce thermal resistance by promoting high nucleation site density (where bubbles of steam form on a metal surface).

Boiling is one of the most effective methods to cool high-power electronic devices and maintain a uniform temperature distribution. Boiling enhancement coatings made of advanced materials can facilitate effective nucleate boiling. Today, these are applied on a flat surface, but research shows a coral-like heat sink design with internal groove-like features has the highest potential for external heat transfer coefficients with two-phase immersion cooling.

Intel envisions these ultra-low thermal resistance 3D vapor chamber cavities integrated within coral-shaped immersion cooling heat sinks created using additive manufacturing.

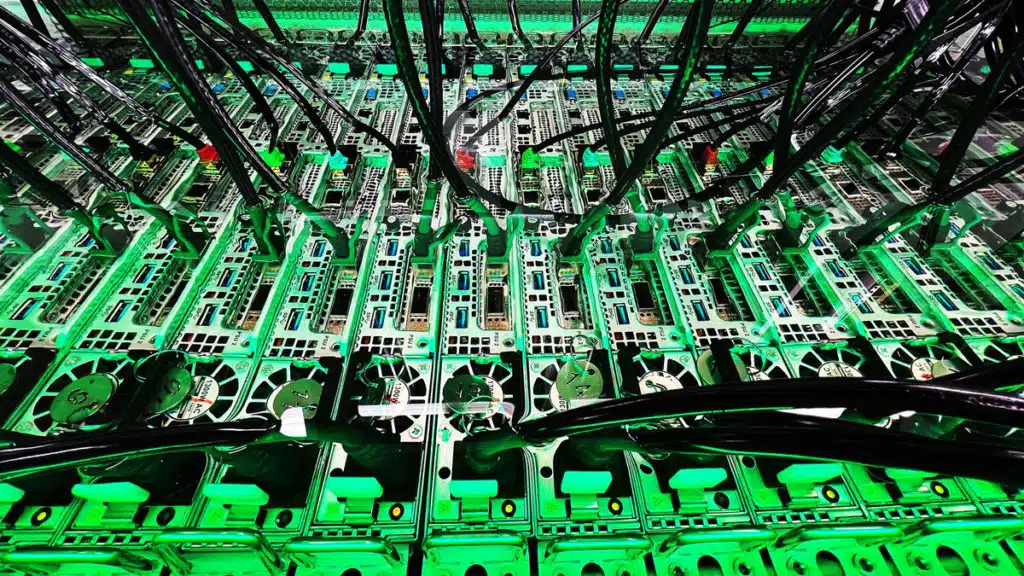

Another approach Intel researchers are pursuing uses arrays of fluid jets to cool the highest-power devices. Unlike typical heat sinks or traditional cold plates that pass fluid over a surface, the cooling jets route fluid directly at the surface. The thermal lid that contains the jets can be attached directly to the top of a standard lidded package, eliminating thermal interface material and reducing thermal resistance. With multi-chip modules becoming increasingly difficult to cool, this technology can be customized for each construction and can target hot spots effectively, enabling the processor to run at a lower temperature with a 5% to 7% increase in performance for the same power.

From its processor designs to the data center system level, Intel remains focused on extending Moore’s Law while increasing energy efficiency.