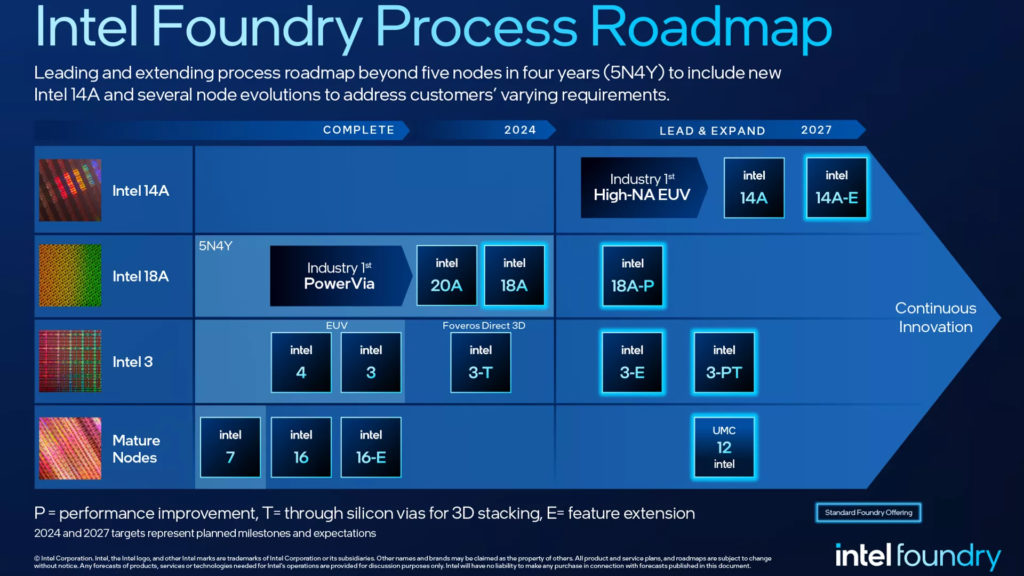

The yields of Intel 18A, a process technology that Intel had expected to return the company to process leadership in 2025, having been described as being “leading-edge,” is seeing yields as poor as 10%, according to a new report out of South Korea that discusses some of Intel’s latest setbacks, including the leave of Pat Gelsinger. The allegation comes several months after Reuters published a report about how Intel’s manufacturing business had suffered a setback, with silicon wafers sent through the 18A process failing one of its major customer’s tests (i.e., Broadcom). An Intel spokesperson is reported to have said that 18A was “healthy and yielding well,” but Broadcom seemed to think differently, with a rep saying that the company “have not concluded that evaluation.”

The foundry performance, into which money and manpower were poured, did not meet Gelsinger’s expectations. The industry analyzed that the yield of the 18 Angstrom (equivalent to 1.8 nanometers) process that Intel was planning to mass produce next year was less than 10%. As a result, its customer Broadcom canceled its semiconductor orders for Intel. The vicious cycle began as advanced process mass production was not realized and expected sales were not generated. In the end, Intel had to postpone or cancel its plans to build production lines in Ohio, the US, and Europe. As a result, the US government’s semiconductor subsidy scheduled for Intel was also cut by $640 billion from the previous amount to $7.86 billion.