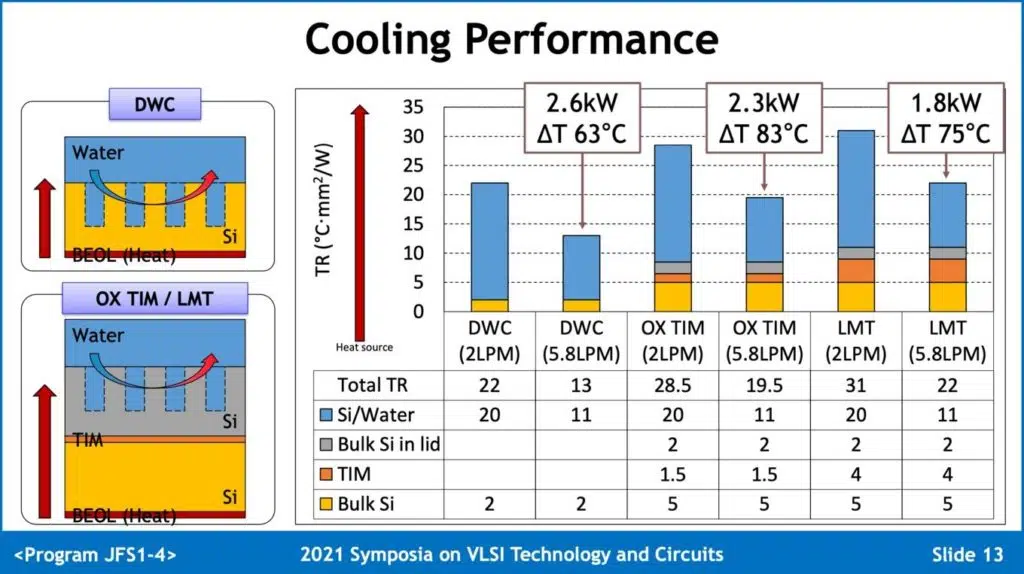

Future processors could boast built-in water cooling thanks to ambitious research by the world’s leading semiconductor foundry, TSMC. During a recent symposium, the Taiwanese company demonstrated three water cooling methods that would integrate water channels directly into a chip’s design. Out of the three methods, TSMC had the most luck with one leveraging direct water cooling, in which the water has its own circulating channels etched into the silicon. That method allowed for up to 2.6 kW of heat dissipation and a temperature delta of 63 degrees Celsius. Of course, it’ll probably be a while before any of this technology reaches the mainstream.

The company further tested three types of water cooling designs: one with only direct water cooling (DWC), where water has its own circulating channels etched directly into the chip’s silicon as part of the manufacturing process; another design with water channels being etched into their own silicon layer on top of the chip proper, with a Thermal Interface Material (TIM) layer of OX (Silicon Oxide Fusion) that carried heat from the chip to the watercooling layer; and lastly a design which swapped the OX layer for a simpler, cheaper liquid metal solution.

Sources: HardwareLuxx, Tom’s Hardware