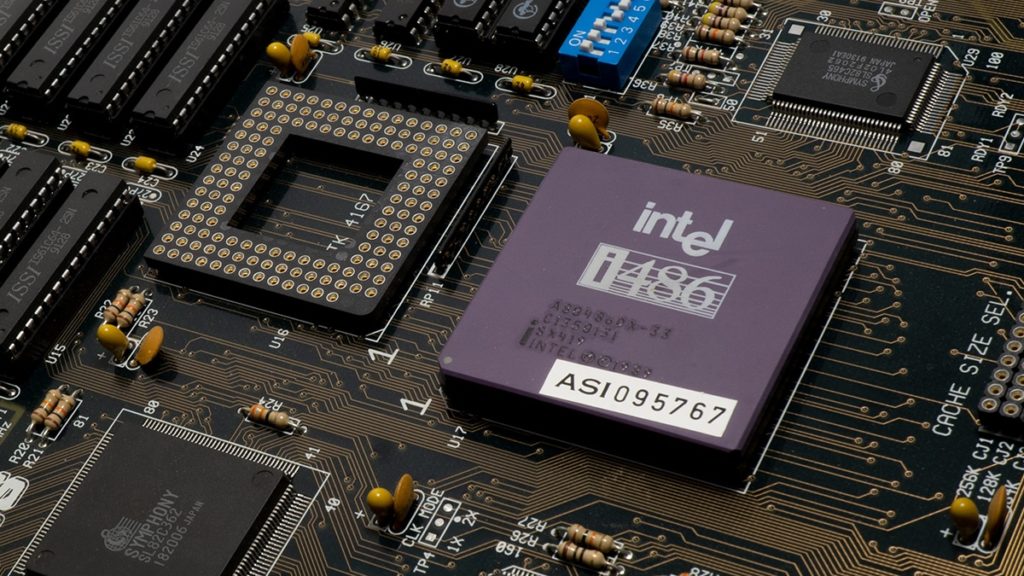

Taiwan has implemented new export restrictions that prevent Russia and Belarus from receiving decent CPUs. Among the processors that are banned include chips with frequencies that exceed 25 MHz, offer performance greater than 5 gigaFLOPS or higher and an arithmetic logic unit with an access width of 32 bits or more, and those with “more than one data or instruction bus or one serial communication port that provide direct external interconnection between parallel microcircuits at a transfer rate of 2.5 MB/s.” ICs with “more than 144 pins or basic gate propagation delay time of less than 0.4 nanosecond” are also banned from exportation to Russia and Belarus. One of the first Intel processors that could hit 25 MHz was the i80386, first released in 1985.

Alignment and exposure equipment for wafer production using photo-optical or X-ray methods, such as lithography equipment which includes image projection and transfer, step-and-repeat operation (direct step on wafers) or step-and-scan operation (scanners) processing, as well as scanning electron microscopes designed for automatic inspection of patterns of semiconductor devices are under the ban as well.

Semiconductor equipment has become a main category of Taiwan’s machinery exports in terms of export value, accounting for 32.0% of total export value in 2021, with China, Hong Kong, Singapore and the US being major markets.

Source: DigiTimes