Build Quality

As we already know the SilverStone NJ700 features a fanless design. Normally, quiet power supplies utilize 120mm or larger overhead fans which have come to be the preferred standard for quiet cooling environments due to the ability to move a larger volume of air at slower speeds than a smaller diameter fan.

However, the SilverStone N7600 eschews a fan altogether for the ultimate in quiet cooling form factor. While this is great for quiet computing environments the key criteria in our evaluation are whether or not the cooling solution is sufficient, not necessary its sound level or form factor.

External Build Quality

The exterior of the SilverStone NJ700 is just about, if not, identical to the NJ600 we reviewed some time ago. The external build quality of the SilverStone NJ700 differs from what we see from a lot of power supplies in one immediate way; this unit is silver as opposed to black and that is a nice change of pace.

Oddly, though, the application of SilverStone branding to this housing is incomplete (just like we saw with the NJ600) as when we look at the top of the housing we see where the outline for the PRIME logo still exists from when this housing is used by Seasonic. Moving on, this unit is fanless and, as such, the housing is heavily perforated. The hexagonal mesh that makes up the housing of the SilverStone NJ700 covers all of the facets of the unit save for the bottom and a small portion of the front where the cables connect to the unit.

The SilverStone NJ700 comes in at a total length of ~6 5/8 inches while the cables come in at a length of ~20″ to 30″ to the first or only connector. Additionally, the cables are all FlexForce style cables (which is excellent) or standard wire loom and it is fully modular.

Internal Build Quality

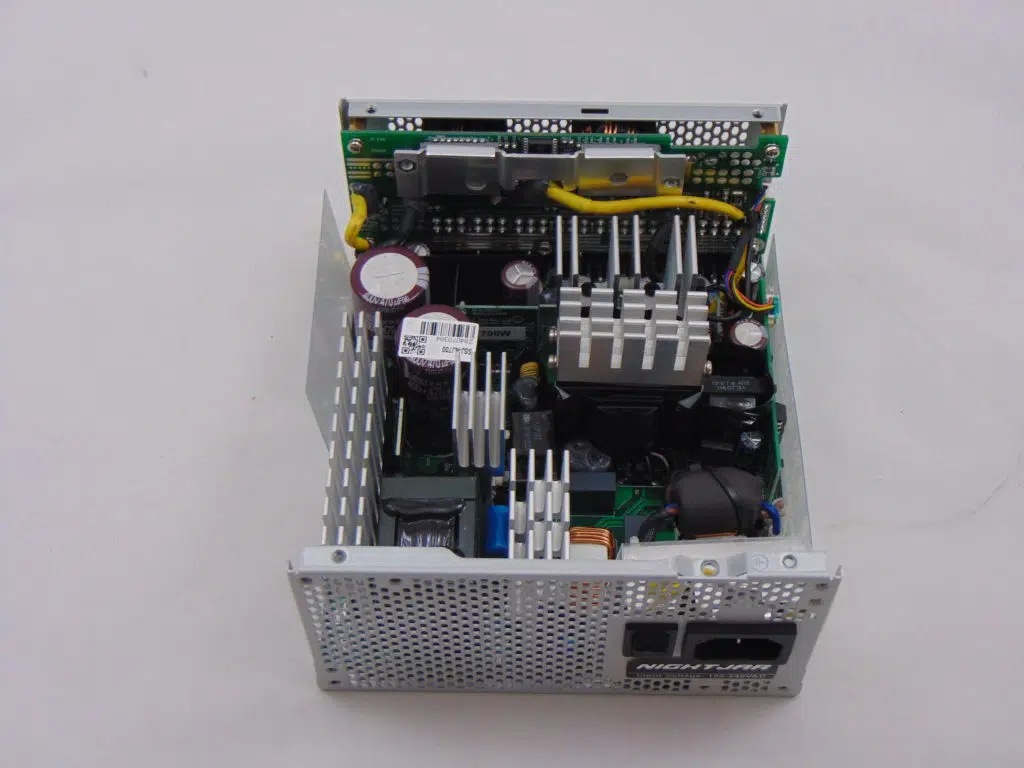

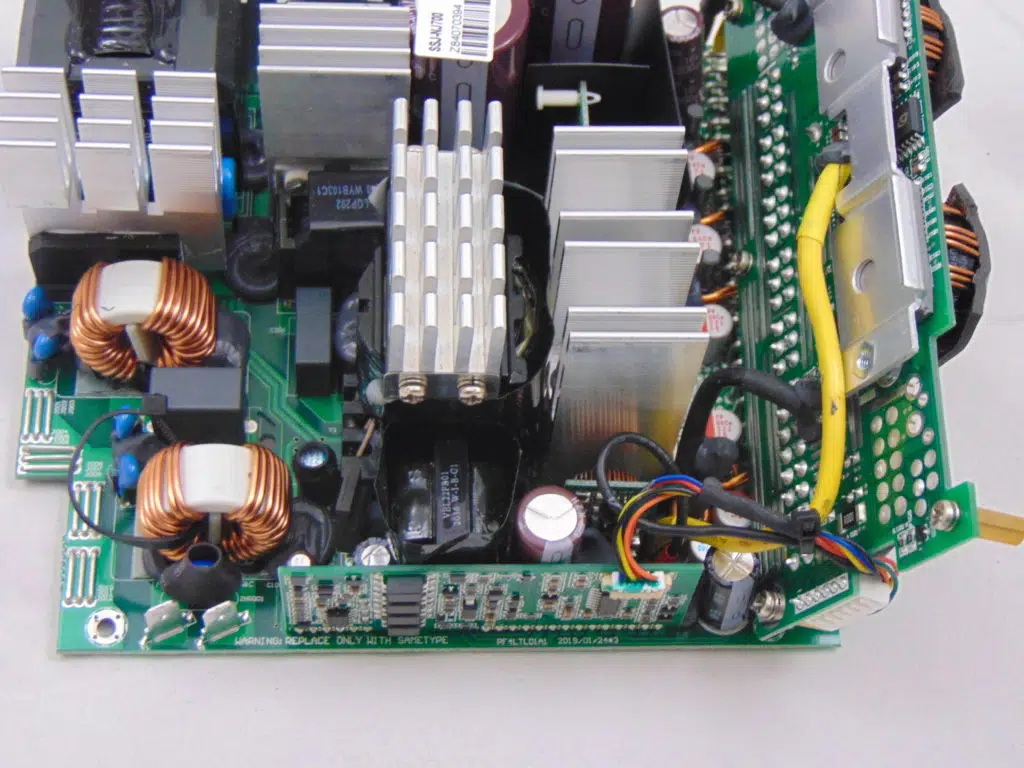

Once we open the top of the SilverStone NJ700, we see the same basic platform that was used with the NJ600. However, that is probably to be expected. The topology is, once again, a full-bridge resonant LLC primary with a synchronous rectification secondary and DC-DC VRM’s for the minor rails. The biggest difference we see between the NJ600 and the NJ700 is the fact that a heatsink has been added to the main transformer. Lastly, the soldering is generally very neat which is generally the case with Seasonic built units.

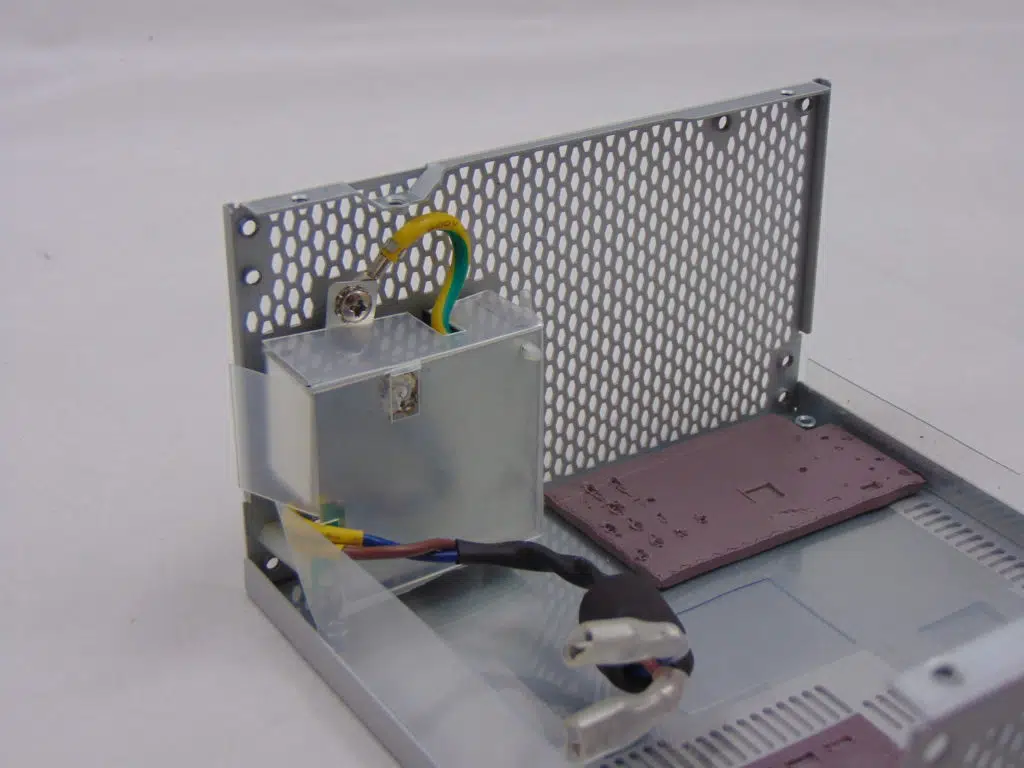

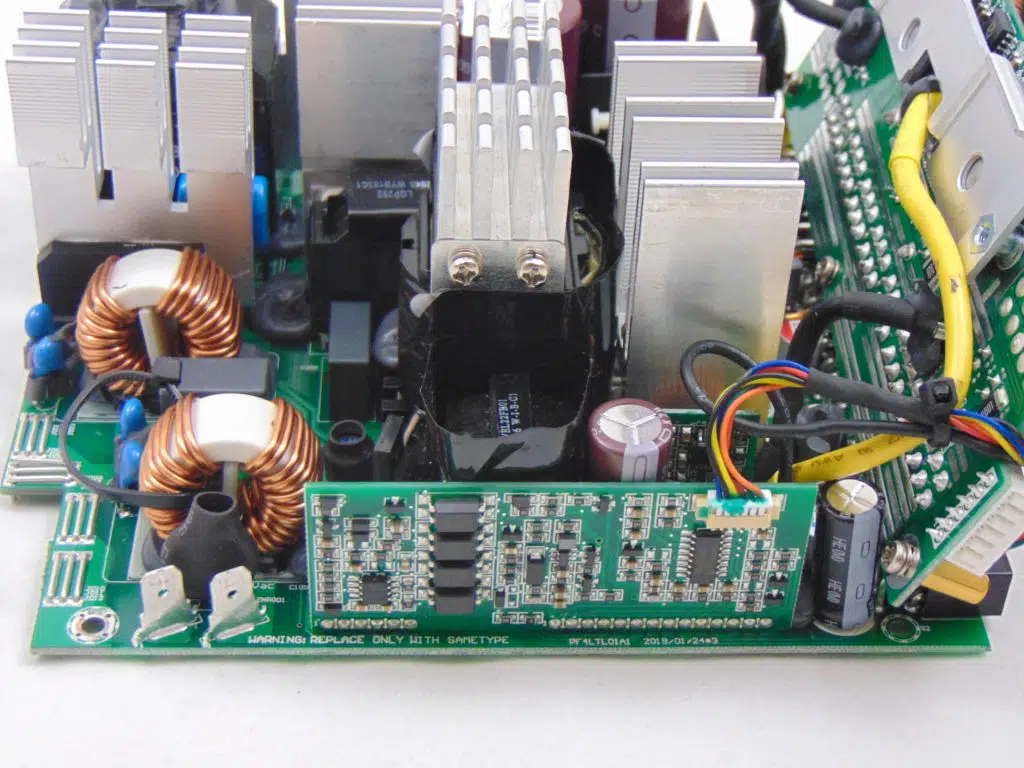

On the primary side, the SilverStone N700 input filtering begins up on the housing itself with a PCB in a metal housing (but not a self-contained can). This housing contains X capacitors, Y capacitors, and a coil. The input filtering then trails onto the main PCB where we find that it is complete. The bridge rectifiers are found next sandwiching an aluminum heatsink.

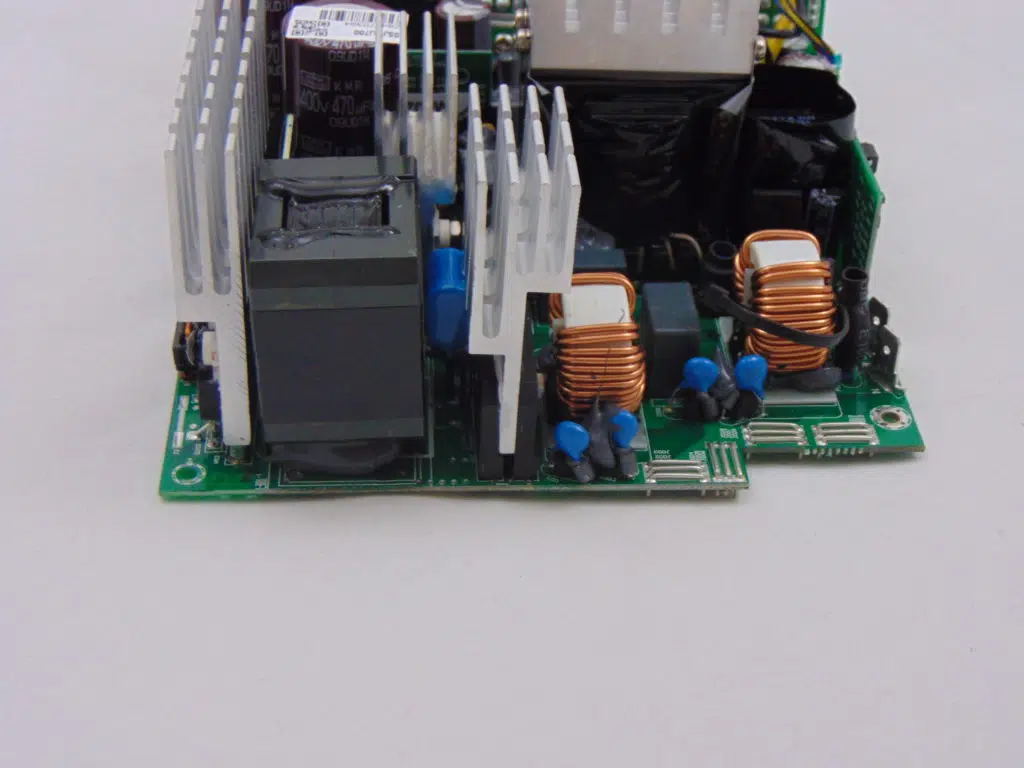

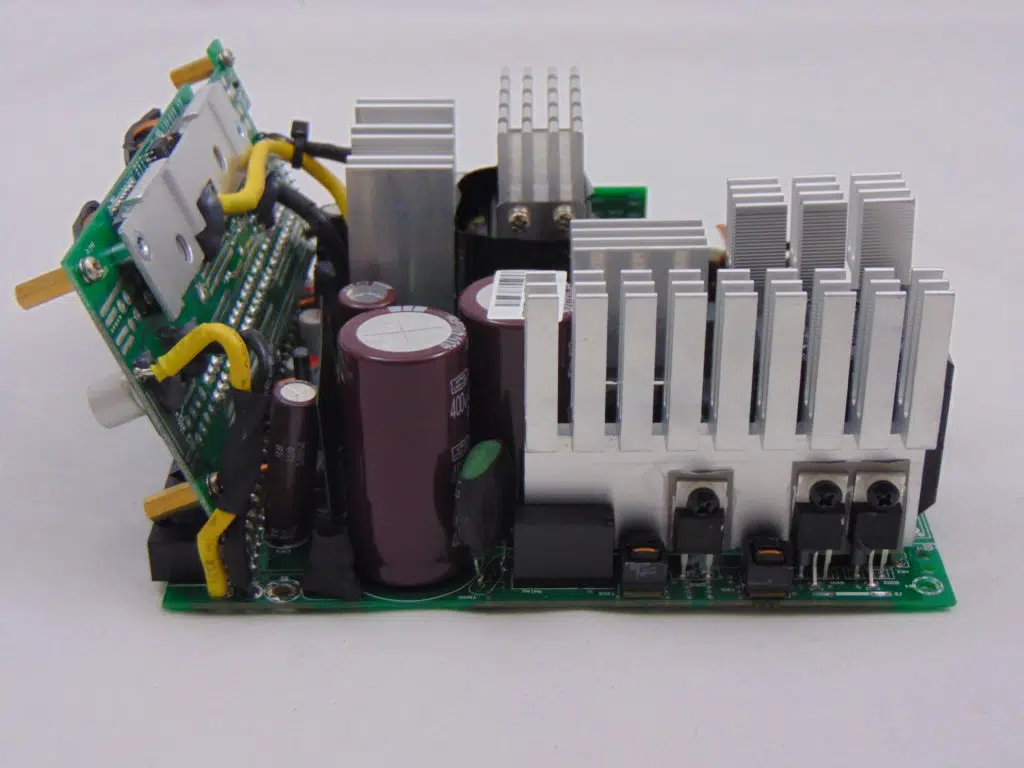

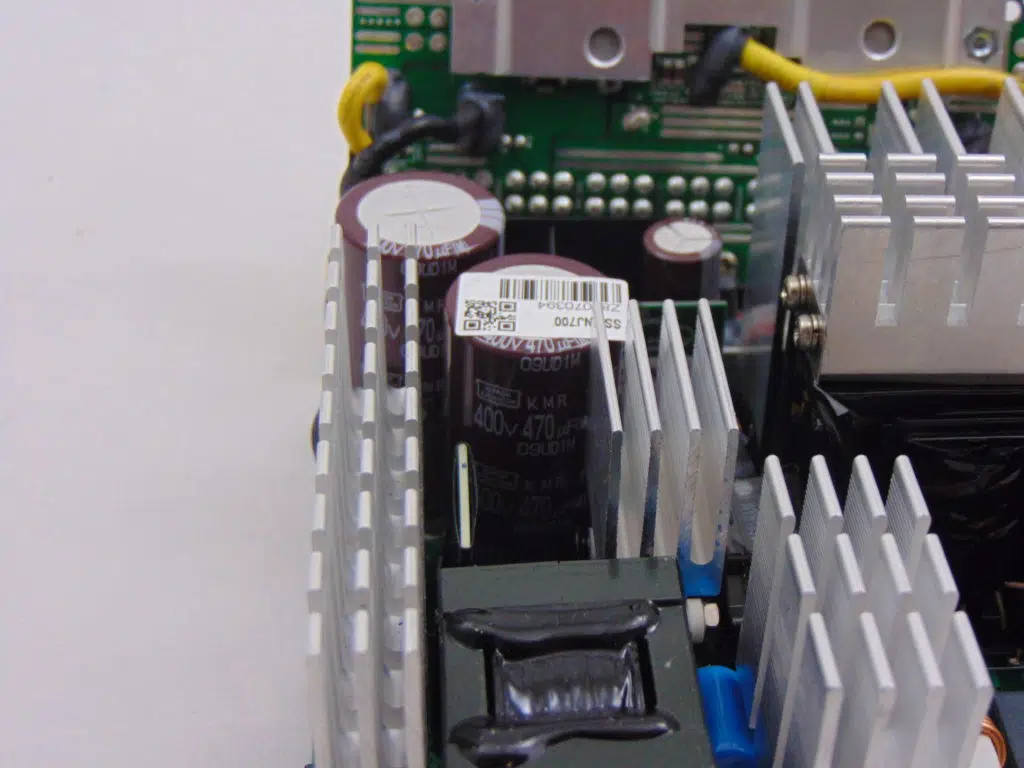

As we move around to the primary side proper, we find a coil followed by the APFC power components on a heatsink. Behind this heatsink, we find the main input capacitors which are provided by Nippon Chemi-con. These capacitors are rated at 400v 470uF 105C. Between these capacitors and the APFC coil, we see the main switchers attached to the heatsink towards the center of the PCB.

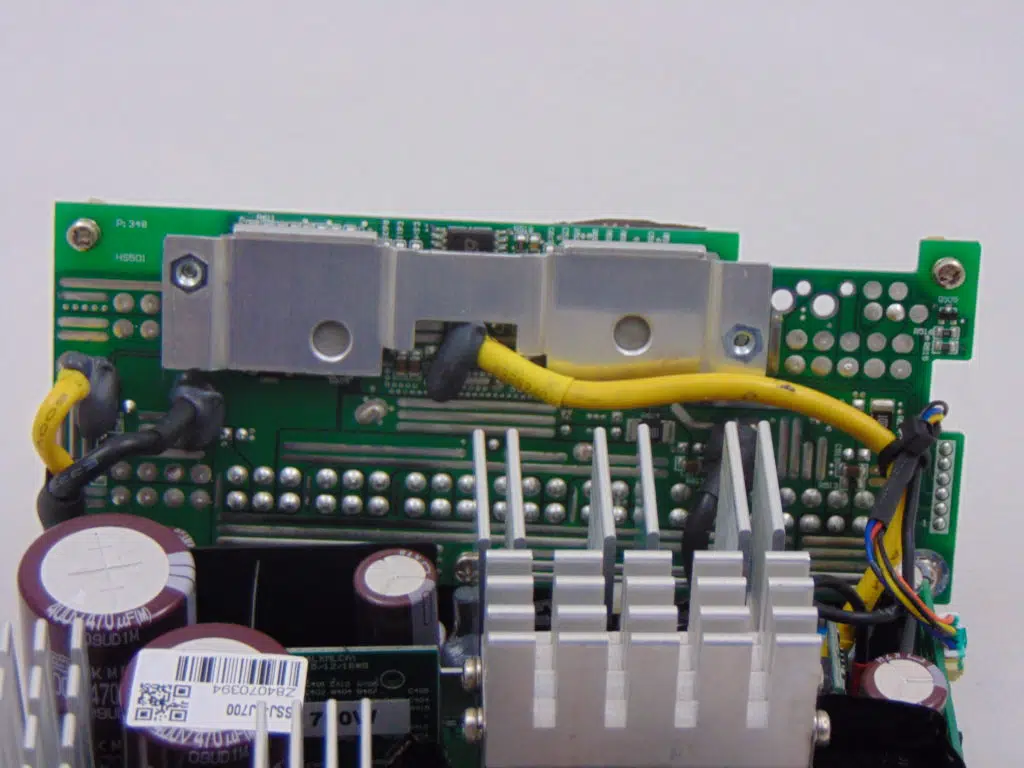

Moving over to the “secondary side,” we see a large heatsink which is actually two heatsinks bridged by a screwed in aluminum piece and this is used for helping to cool the 12v MOSFETs that are on the rear of the main PCB (these components also use the case housing as part of the overall cooling scheme). We also so the aforementioned transformer with a heatsink attached to it as well.

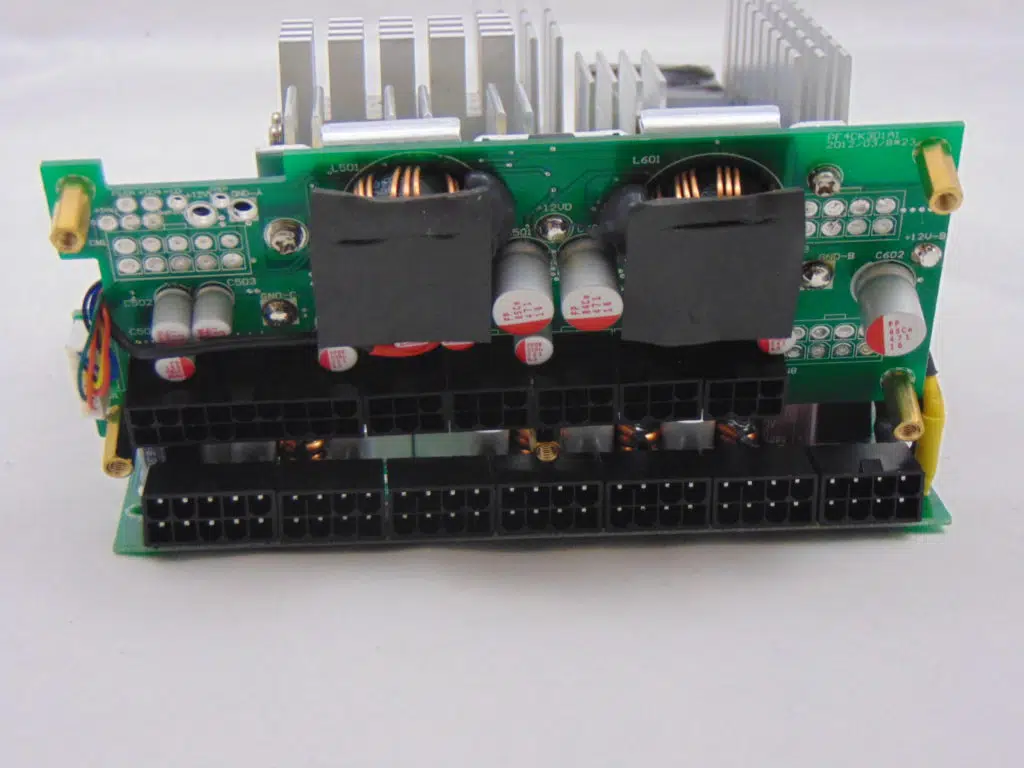

Instead of finding the VRMs on an add-in PCB, we find the VRMs up on the modular PCB. Next, the standard capacitors come to us from Nippon Chemi-con and Rubycon while the solid capacitors come to us from FPCAP. Moving on to the modular PCB, we see the modular connectors as well as the DC-DC VRMs for the minor rails and a heatsink on the rear for them. The capacitors we find populating this very clean PCB are solid capacitors from FPCAP.

Build Quality Summary

Today’s SilverStone NJ700 is based on the same PRIME derived platform used in Seasonic’s own PRIME 600 Titanium Fanless and the SIlverStone NJ600. The overall build quality of this unit is excellent with the only things to quibble about being the same nitpicks we had for the NJ600.

If we skip that though, and move to the interior build quality, we again see a modern design that is extremely well executed with excellent attention to detail in all aspects. The component selection is again well matched to this integration effort as we see Nippon Chemi-con (standard), Rubycon (standard), and FPCAP (solid) capacitors today. So, things look excellent to start the day off with. Let’s move on now to the load tests and see how this unit does there!