Load Testing

For those of you that are curious as to some of the reasoning and equipment behind our PSU testing program here at TheFPSReview, we have put together an introduction for you. This program is based on what the author developed at [H]ardOCP and utilizes the equipment bequeathed to the author by Kyle Bennett. The testing we are conducting today is exactly as described in that document and start with our 120v, 100v, Torture, and 80 Plus Tests.

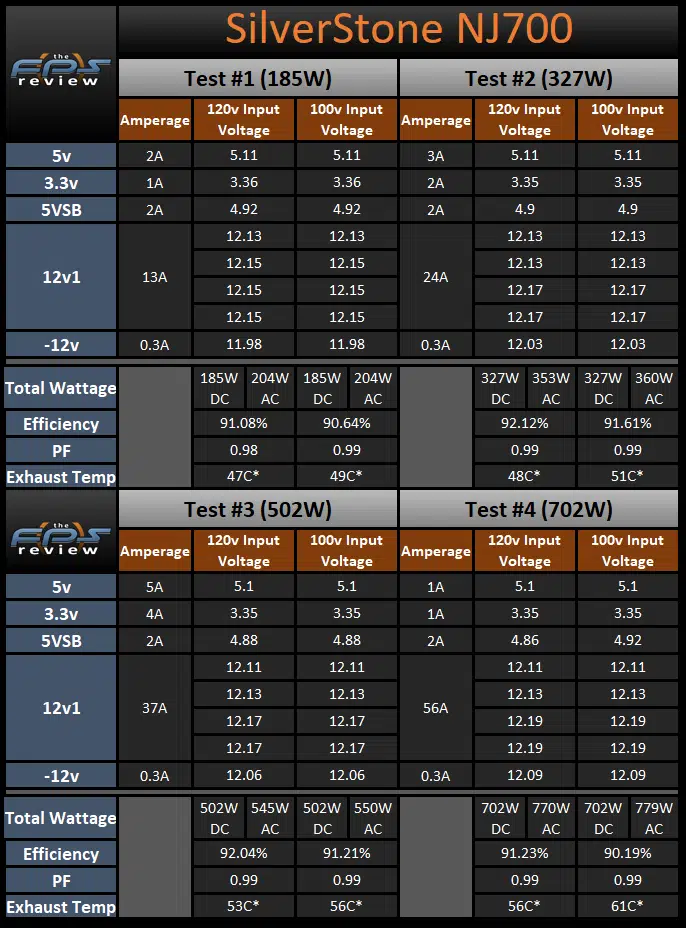

120v and 100v Load Testing Results

Test #1 is equal to approximately 25% of the rated capacity of the SilverStone NJ700 at 45c. This makes Test #1 equal to 185W by loading the 12v rail to 13a, the 5v rail to 2a, the 3.3v rail to 1a, the +5vsb to 2a, and the -12v to 0.3a. The results of Test #1 show the main positive DC output rails starting above nominal. The efficiency for this unit is starting off in excellent shape at a value of 91.08% at 120v AC input and 90.64% at 100v AC input. We see the housing temperature is 47C at 120v AC input and 49C at 100V AC input.

Test #2 is equal to approximately 50% of the rated capacity of the SilverStone NJ700 at 45c. This makes Test #2 equal to 327W by loading the 12v rail to 24a, the 5v rail to 3a, the 3.3v rail to 2a, the +5vsb to 2a, and the -12v to 0.3a. Test #2 sees mixed results in the DC output voltages relative to what we saw with Test #1. The largest changes are up to a 0.02v increase on the 12v rail followed by a 0.01v drop on the 3.3v rail. The 5v rail, however, remained even with Test #1. The efficiency has moved up to 92.12% at 120v AC input and 91.61% at 100v AC input. We see a housing temperature of 48C at 120v AC input and 51C at 100V AC input.

Test #3 is equal to approximately 75% of the rated capacity of SilverStone NJ700 at 45c. This makes Test #3 equal to 502W by loading the 12v rail to 37a, the 5v rail to 5a, the 3.3v rail to 4a, the +5vsb to 2a, and the -12v to 0.3a. Test #3 mixed results in the DC output voltages relative to what we saw with Test #1. The largest changes are up to a 0.02v decrease on the 12v rail followed by a 0.01v drop on the 5v rail. The 3.3v rail, however, remained even with Test #2. The efficiency in Test #3 moves down to 92.04% at 120v AC input and up to 91.21% at 100v AC input. We see a housing temperature of 53C at 120v AC input and 56C at 100V AC input.

Test #4 is equal to approximately 100% of the rated capacity of the SilverStone NJ700 at 45c. This makes Test #4 equal to 702W by loading the 12v rail to 56a, the 5v rail to 1a, the 3.3v rail to 1a, the +5vsb to 2a, and the -12v to 0.3a. In the final regular test, we see the 12v rail move up by up to 0.02v. The minor rails, however, stay even with their Test #3 values. The efficiency has dropped as we see it come in at 91.23% at 120v AC input and 90.19% at 100v AC input. We see a housing temperature of 56C at 120v AC input and 61C at 100V AC input.

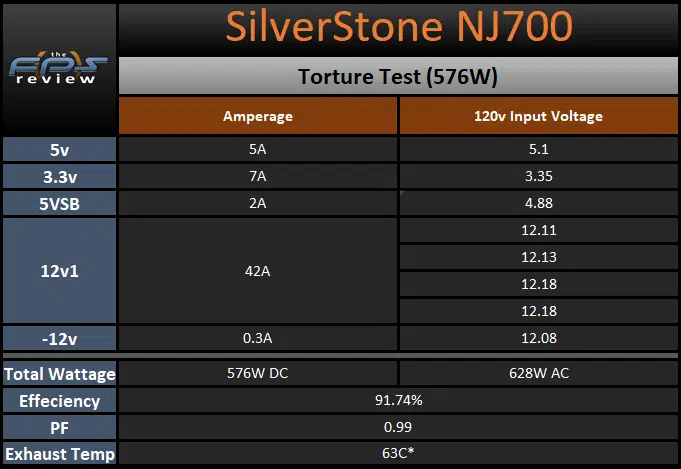

Torture Test

The Torture Test is equal to approximately 80% of the rated capacity of the SilverStone NJ700 at 45C. This makes the Torture Test equal to 576W by loading the 12v rail to 42a, the 5v rail to 7a, the 3.3v rail to 5a, the +5vsb to 2a, and the -12v to 0.3a. At the end of the Torture Test, the NJ700 is still doing well. The DC output voltages are generally in line with what we have been seeing in the 120v load tests. The efficiency is excellent as we see a value of 91.74% and the housing temperature is 63C.

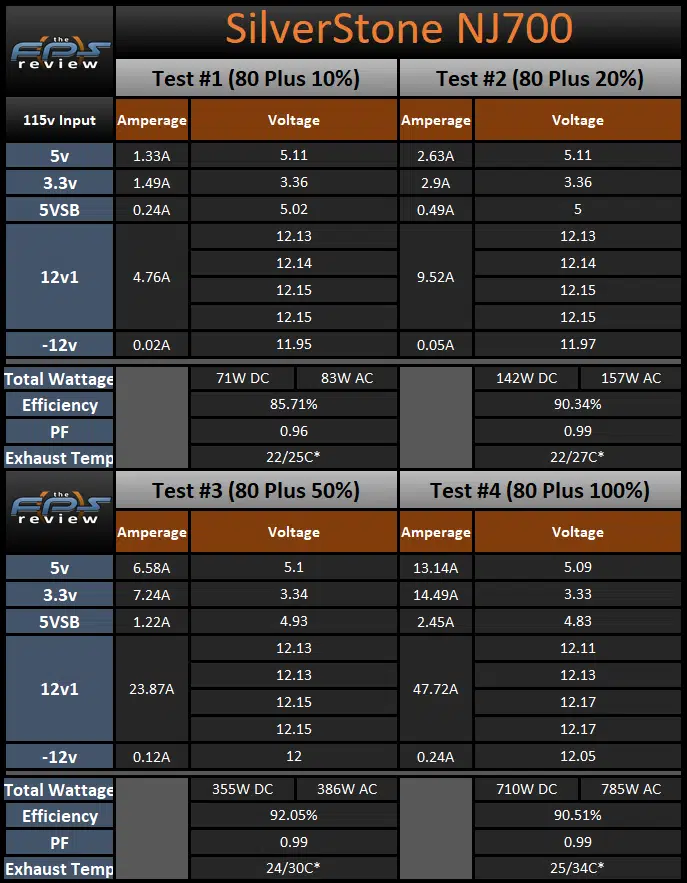

80 Plus Load Testing Results

As we see here, the SilverStone NJ700 posts efficiency values of 90.34%-92.05%-90.51% efficient using 80 Plus’ load testing parameters. This puts the unit under the 80 Plus Titanium standard in the 25% and 50% tests by up to 1.95%. However, we do use different equipment than 80 Plus for our testing and there is always a bit of component variation.

Load Testing Summary

Much like the SilverStone NJ600 before it today, the SilverStone NJ700 did an excellent job in our initial load testing. When we look at the voltage regulation, we see that the NJ700 had peak changes of 0.04v on the 12v rail, 0.01v on the 5v rail, and 0.01v on the 3.3v rail. These absolute values are easily in the specification and simply awesome. In fact, they are better than all of the 700W units we have seen to date and may well be the best we see for quite some time!

When we look at the efficiency values posted today, we see that the NJ700 ranged from 91.08% to 92.12% efficient at 120v AC input and 90.19% to 91.61% efficient at 100v AC input. When we look at this units 80 Plus performance we see that it posted values of 90.34%-92.05%-90.51% which miss the 80 Plus Titanium standard by up to 1.95%! Lastly, the housing temperature peaked at 56C at 120v AC input, 61C at 100v AC input, and 63C during the Torture Test. With excellent starting results in today’s testing, let’s move on to the Transient Load Tests.