DC Output Quality

For those of you that are curious as to some of the reasoning and equipment behind our PSU testing program here at TheFPSReview, we have put together an introduction for you that shares a lot of the behind the scenes of the program. This program is based on what the author developed at [H]ardOCP and utilizes the equipment bequeathed to the author by Kyle Bennett. The testing we are conducting today is exactly as described in that document and will continue with our examination of the DC Output Quality.

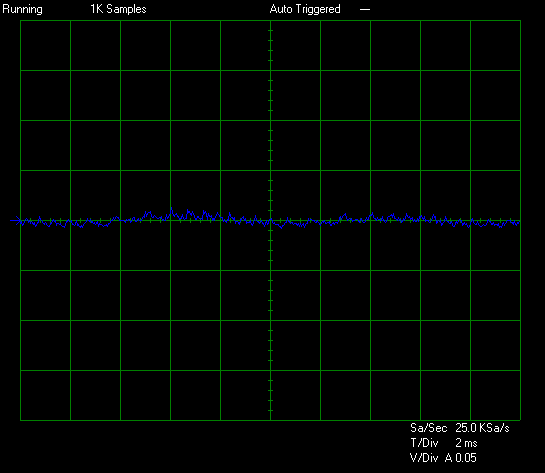

Control Test Graphing

This image is the blank background control test on an unused connector from our SM-8800 during the testing of the SilverStone NJ700. This lets us determine what the background noise looks like during testing.

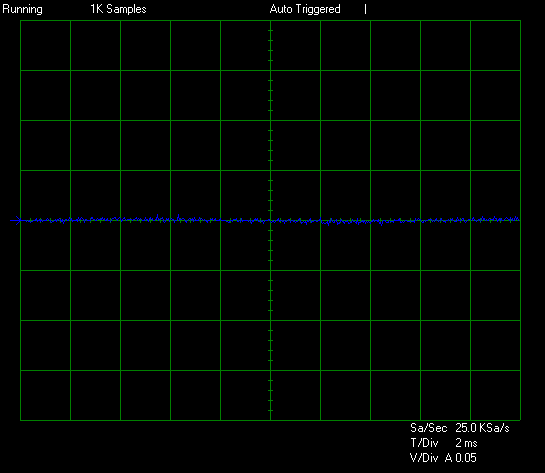

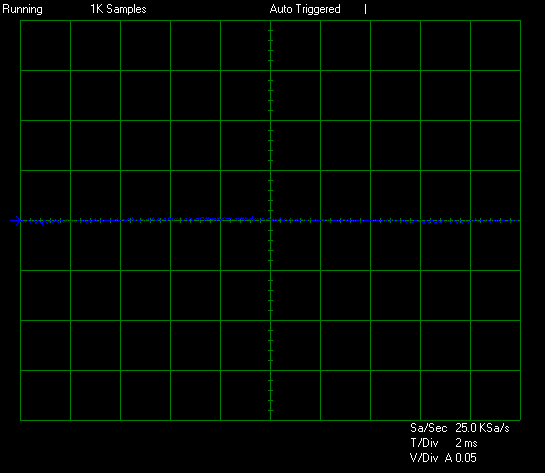

120v Input

100v Input

Test #1 is equal to approximately 25% of the rated capacity of the SilverStone NJ700 at 45c. This makes Test #1 equal to 185W by loading the 12v rail to 13a, the 5v rail to 2a, the 3.3v rail to 1a, the +5vsb to 2a, and the -12v to 0.3a. The SilverStone NJ700 is starting off in excellent shape. All of the rails we monitor are peaking at ~10mV of ripple/noise.

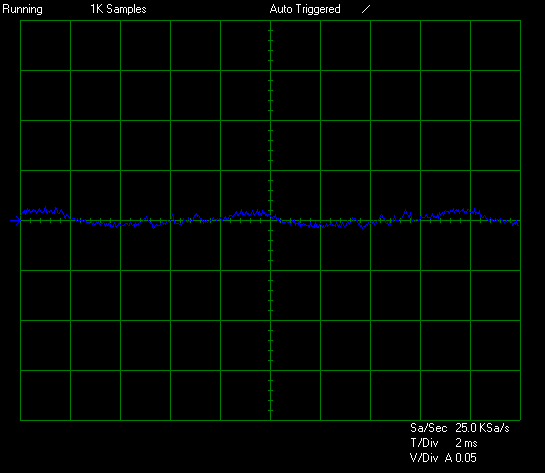

120v Input

100v Input

Test #2 is equal to approximately 50% of the rated capacity of the SilverStone NJ700 at 45c. This makes Test #2 equal to 327W by loading the 12v rail to 24a, the 5v rail to 3a, the 3.3v rail to 2a, the +5vsb to 2a, and the -12v to 0.3a. Test #2 sees only minor changes as the 12v rail is coming in at ~20mV of ripple/noise while the minor rails are coming in at ~10mV of ripple/noise.

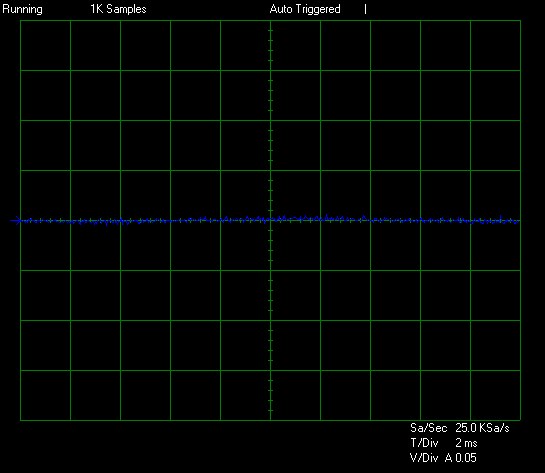

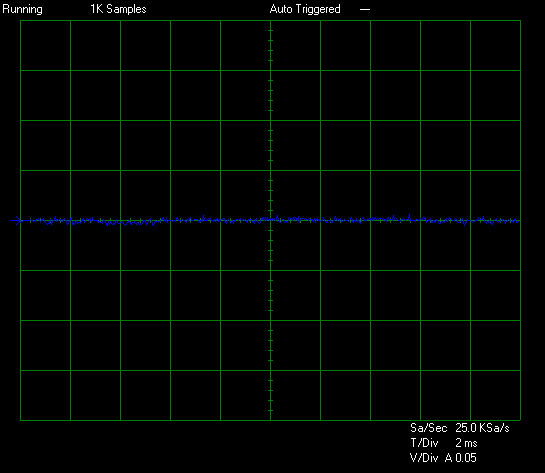

120v Input

100v Input

Test #3 is equal to approximately 75% of the rated capacity of SilverStone NJ700 at 45c. This makes Test #3 equal to 502W by loading the 12v rail to 37a, the 5v rail to 5a, the 3.3v rail to 4a, the +5vsb to 2a, and the -12v to 0.3a. Test #3 sees the 12v rail peaking at ~20mV of ripple/noise again while the minor rails are coming in at ~10mV of ripple/noise.

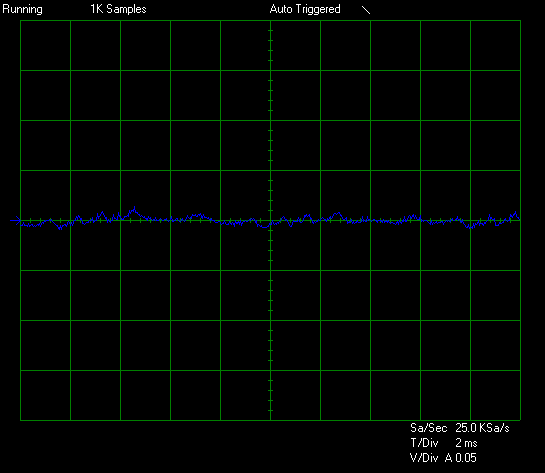

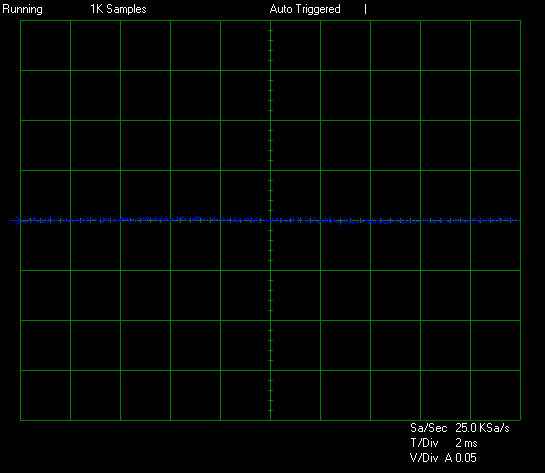

120v Input

100v Input

Test #4 is equal to approximately 100% of the rated capacity of the SilverStone NJ700 at 45c. This makes Test #4 equal to 702W by loading the 12v rail to 56a, the 5v rail to 1a, the 3.3v rail to 1a, the +5vsb to 2a, and the -12v to 0.3a. In the final regular test, we see the 12v rail peaking at ~25mV of ripple/noise while the minor rails are peaking at ~10mV of ripple/noise.

Torture Test

The Torture Test is equal to approximately 80% of the rated capacity of the SilverStone NJ700 at 45C. This makes the Torture Test equal 576W by loading the 12v rail to 42a, the 5v rail to 7a, the 3.3v rail to 5a, the +5vsb to 2a, and the -12v to 0.3a. At the end of the Torture Test, we see the 12v rail peaking at ~20mV of ripple/noise while the minor rails are peaking at ~10mV of ripple/noise.

DC Output Quality Summary

The overall DC Output Quality of the SilverStone NJ700 is excellent. The NJ700 ended up posting a peak trace amplitude on the 12v rail of ~25mV followed by ~10mV on the 3.3v rail and ~10mV on the 5v rail. The worst absolute value among these hits less than ~25% of the ATX12v specification limit. In a relative sense, this unit was better than the Antec NEO ECO GOLD ZEN 700W and the Cougar BXM 700. So, it seems that while this unit is quiet in audio sense it is also very quiet in an electrical sense! Let’s move on now and see how all of this wraps up!